Where Are We in the 3D Printing Industry?

Perhaps next to artificial intelligence and big data, nothing boggles-and excites-the mind than 3D printing. The idea that one can already build many things, from gear to a house, sure sounds lucrative.

But what’s the real picture? Where are the world in developing such technology?

The Impressive Growth of Additive Manufacturing

The popularity of 3D printer supply in the UK highlights the growth of the industry of additive manufacturing. In a report by Mordor Intelligence, its market value was over $10 billion in 2019. By 2025, it can reach at least $63 billion with a compound annual growth rate (CAGR) of a whopping 29%.

North America remains its leading market, but Europe is one of the top continents. The UPS research suggested that both of these regions accounted for almost 70% of the total market share in 2016. Asia, meanwhile, followed at 27%.

The same report cited the top uses of 3D-printed products. About 29% were for creating functional parts, while 10% were for tooling and molding. Over 15% of the application was for fit-and-finish components. Only 10% of the users invested in technology for proof of concept.

Why Is Additive Manufacturing Popular?

What’s driving behind the growth of additive manufacturing? It’s a mixture of different factors. One of these is multiple-entry penetration.

The UPS report enumerated some of the industries that are currently using 3D printing for different applications:

- Electronics

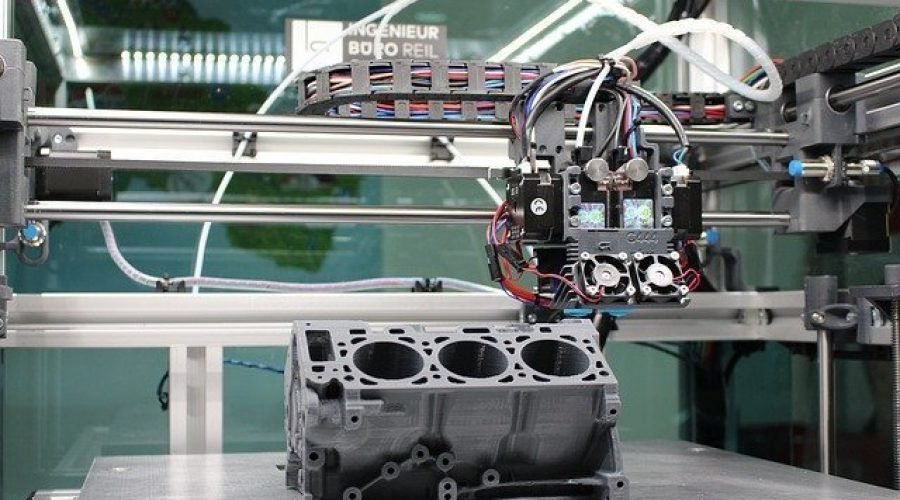

- Automotive

- Healthcare

In the first two fields, additive manufacturing is an essential tool in prototyping. It allows companies to visualise the product better before it hit production. In the process, they can already identify potential problems and determine possible solutions. All these can help reduce the production costs of goods. The consumers can benefit now as these products become less expensive or competitive once they are in the market.

Additive manufacturing will also play a vital role in healthcare. For example, one of its essential uses is the production of hearing aids. Some schools are also using 3D-printed body parts to allow students to work on tools that closely resemble organs.

It may also be critical in engineering organs, such as the heart. In a 2019 study, researchers from the Carnegie Mellon University revealed that they already developed a technique that could already help them design the body’s only cardiac muscle.

The University of Minnesota team, meanwhile, developed a 3D-printed device aimed to help those with spinal cord injuries regain some function.

Many of these projects are still proof of concepts, though, and it may take a while before they are available in mass-production. Nevertheless, the impact can save many lives. For example, additive manufacturing may help augment the need for organ transplants.

The Challenges of Additive Manufacturing

Additive manufacturing helps improve product development by 16% and increase efficiency by 10%. It may even reduce production costs by over 7%. Despite these benefits, it still faces many challenges.

One of these is the acquisition costs. Small-business entrepreneurs can work with a 3D printer supply in the UK and get a unit for less than £3,000. For industrial-scale production, though, a person or company may need to shell out thousands of pounds.

Materials may also not be readily available, and to create more complex designs, it may be necessary to combine some of them.

Additive manufacturing still needs to deal with limitations, but the advantages will already allow users to start somewhere, such as a business.